A gear motor develops an output torque at its shaft by allowing hydraulic pressure to act on gear teeth. A gear motor consists basically of a housing with inlet and outlet ports, and a rotating group made up of two gears. One gear is attached to a shaft that is connected to a load. The other gear is the driven gear. The various commonly used gear motors are shown in Fig.2.16.

In a gear motor, the imbalance necessary for motor operation is caused by gear teeth unmeshing. The inlet is subjected to system pressure and the outlet is at return line pressure. As the gear teeth unmesh, all teeth subjected to system pressure are hydraulically balanced except for one side of one tooth on one gear tooth. The larger the gear tooth or the higher the pressure,the more torque is produced.

An internal gear motor consists of one external gear which meshes whith the teeth on the inside circumference of a larger gear. A popular type of internal gear motor in industrial systems is the gerotor motor. This motor is an internal gear motor with an inner drive gear and an outer driven gear which has one more tooth than the inner gear. The inner gear is attached to a shaft which is connected to a load. The imbalance in a gerotor motor is cuased by the difference in gear area exposed to hydraulic pressure at the motor inlet.

Fluid pressure acting on these unequally exposed teeth results in a torque at the motor shaft. The larger the gear or the higher the pressure, the more torque will be developed at the shaft. Fluid entering the rotating group of a gerotor motor is separated from the fluide exiting the motor by means of a port plate with kindey-shaped inlet and outlet ports.

When selecting a gear motor, an important consideration is the degree of gear service and gear life based on the load conditions to which the motor will be subjected. Gear motors are divided into three classes. Each class uses different gear sizes to handle specific load conditions. Each class gives about the same life for the gears. The American Gear Manufacturer's Association has defined three operating conditions commonly found in industrial service and has established three standard gear classifications to meet these conditions:

Class I For steady loads within the motor rating of 8 hours per day duration, or for intermittent operation under moderate stock conditions.

Class II For 24-hour operation at steady loads within the motor rating, or 8-hour operation under moderate shock conditions.

Class III For 24-hour operation under moderate shock condition, or 8-hour operation under heavy shock conditions.

For conditions that are more severe than those covered by Class III gears, a fluid drive unit may be incorporated in assembly to cushion the shock to an acceptable value.

To achieve multiple speeds, separte units are available with a transmission comparable to that of an automobile. These units must be assembled with the motor and the driven machine. Because the amout of power lost in gearing is very small, the multiple drive has essentially constant horsepower. In other words, as the output speed is decreased, the torque is increased. Generally, this means that larger shaft sizes are needed for the output side.

This is the blog about industry automation, where is original research and aggregation of content about Industrial automation control system and other industry devices, motor, accessories, CNC solution, etc.

2016年9月22日星期四

2016年9月20日星期二

Inserting Parametric PLC Modules

A programmable logic controller (PLC) or programmable controller is a digital computer that is used to automatically regulate the industrial process. For example, comtrolling machinery on assembly lines of factor. This controller is designed to meet a range of industrial activities such as multiple inputs and output arrangements, extended temperature ranges, giving immunity to electrical noise, and providing resistance to vibration. The programs, designed to regulate the machine operation, are usually stored in a battery-backed or non-volatile memory. A PLC is an instance of a real time system becuase output results are needed to be produced in response to input conditions within a time-bound period; else, it will result in an unintended operation. Over the years, the functionality of PLC has evolvoed to accommodate sequential relay control, motion control, process control, distributed control systems, and networking. In PLC, microprocessor controlled interface is inbuilt and is designed to control or monitor some other I/O functions. Being an industrial computer control system, it always monitors the state of input devices and makes decisions on the basis of custom program for controlling the state of devices connected as outputs.

Inserting Parametric PLC Modules

AutoCAD Electrical can generate PLC I/O modules in different graphical styles through parametric generation technique on demand. These modules are generate by a database file and a library of symbol blocks. PLC I/O modules can be inserted as independent symbols. PLC modules behave like other schematic components. These modules are AutoCAD blocks containing attributes for connection points, tagging and so on.

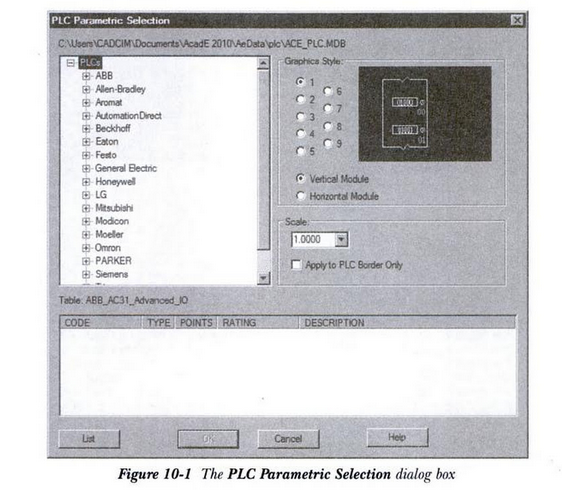

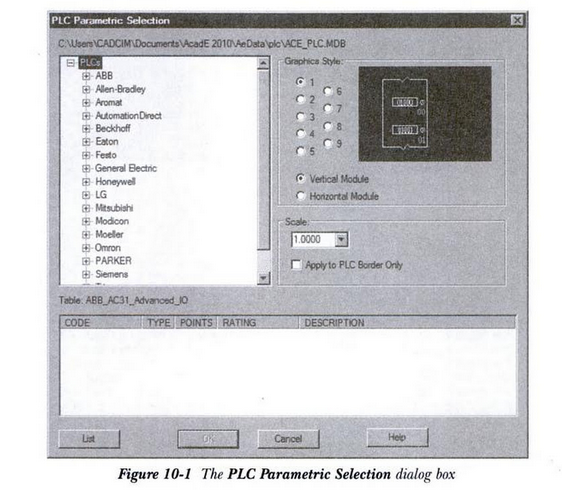

The Insert PLC (Parametric) tool is used to insert a PLC module parametrically. To do so, choose the Insert PLC (PLarametric) button from the Insert Components panel of the Schematic tab; the PLC Parametric Selection dialog box will be displayed, as shown in Figure 10-1. Using this dialog box, you can select the PLC module and its graphics that you want to insert in a drawing. The different options and areas in this dialog box are discussed next.

Manufacture Catalog Tree

The Manufacture Catalog tree, shown in Figure 10-2, displays a list of PLC modules. This list can be filtered by selecting the manufacturer, series, and type of PLC. The data displayed in the Manufacturer Catalog tree is stored in the ace_plc.mdb database file.

You can selet a PLC module from the Manufacturer Catalog tree. To do so, click on the + sign on the requried manfacturers module; PLC modules of the selected manafacturer will be displayed. Select the requried module from the module list; the detailed information of the selected module will be displayed at the lower part of the PLC Parametric Selection dialog box, as shown in Figure 10-3.

After specifying the required values in the I/O Point dialog box, choose the OK button from this dialog box; the I/O Address dialog box will be displayed, as shown in Figure 10-6. Using this dialog box, you can specify the address for the first I/O point.

The values in the Quick picks drop-down list are based on the values that you have specified in the I/O Point dialog box in the Rack and SLOT edit boxes. Select the required value from the Quick picks drop-down list; the value will be displayed in the Beginning address edit box. Alternatively, enter a required value for the first I/0 address of a PLC module in the Beginning address edit box. Note that the other I/O points of a module will be incremented based on the value specified in the Beginning address edit box.

Choose the List button in the I/O Address dialog box; the Report Generator dialog box will be displayed. This dialog box display the information of the selected PLC module.

After specifying the required options in the I/O Address dialog box, choose the OK button in this dialog box; the selected PLC module will be inserted into the drawing.

Inserting Parametric PLC Modules

AutoCAD Electrical can generate PLC I/O modules in different graphical styles through parametric generation technique on demand. These modules are generate by a database file and a library of symbol blocks. PLC I/O modules can be inserted as independent symbols. PLC modules behave like other schematic components. These modules are AutoCAD blocks containing attributes for connection points, tagging and so on.

The Insert PLC (Parametric) tool is used to insert a PLC module parametrically. To do so, choose the Insert PLC (PLarametric) button from the Insert Components panel of the Schematic tab; the PLC Parametric Selection dialog box will be displayed, as shown in Figure 10-1. Using this dialog box, you can select the PLC module and its graphics that you want to insert in a drawing. The different options and areas in this dialog box are discussed next.

Manufacture Catalog Tree

The Manufacture Catalog tree, shown in Figure 10-2, displays a list of PLC modules. This list can be filtered by selecting the manufacturer, series, and type of PLC. The data displayed in the Manufacturer Catalog tree is stored in the ace_plc.mdb database file.

You can selet a PLC module from the Manufacturer Catalog tree. To do so, click on the + sign on the requried manfacturers module; PLC modules of the selected manafacturer will be displayed. Select the requried module from the module list; the detailed information of the selected module will be displayed at the lower part of the PLC Parametric Selection dialog box, as shown in Figure 10-3.

After specifying the required values in the I/O Point dialog box, choose the OK button from this dialog box; the I/O Address dialog box will be displayed, as shown in Figure 10-6. Using this dialog box, you can specify the address for the first I/O point.

The values in the Quick picks drop-down list are based on the values that you have specified in the I/O Point dialog box in the Rack and SLOT edit boxes. Select the required value from the Quick picks drop-down list; the value will be displayed in the Beginning address edit box. Alternatively, enter a required value for the first I/0 address of a PLC module in the Beginning address edit box. Note that the other I/O points of a module will be incremented based on the value specified in the Beginning address edit box.

Choose the List button in the I/O Address dialog box; the Report Generator dialog box will be displayed. This dialog box display the information of the selected PLC module.

After specifying the required options in the I/O Address dialog box, choose the OK button in this dialog box; the selected PLC module will be inserted into the drawing.

2016年9月13日星期二

DSP-BASED Control of Stepper Motors

A stepper motor is an electric machine that rotates in discrete angular increments or steps. Stepper motors are operated by applying current pulses of a specific frequency to the inputs of the motor. Each pulse applied to the motor causes its shaft to the motor causes its shaft to move a certain angle of rotation, called a stepping angle. Since the input signal is converted directly into a requested shaft position without any rotor position sensors or feedback, the stepper motor has the following advantages:

The stepper motor has salient poles on both the stator and the rotor, andnormally only the stator poles hold the poly-phase windings called the controlwindings. Usually stepper motors are classified as:

While each of these types of stepper motors has merit, hybrid stepper motorsare becoming more popular in industrial applications. In this chapter, we focus onthe principles and implementation of a hybrid stepper motor control system usingthe LF2407 DSP controller.

The operation of the stepper motor relies on the simple principle of magneticattraction. This principle states that opposite magnetic poles attract while like polesrepel each other. If the windings are excited in the correct sequence, the rotor will rotate following a certain direction. The basic operation of a stepper motor can beclassified generally as either full step mode or half step mode. These modes are discussed in detail in the following section using the simplified stepper motorconstruction shown in Fig. 8.1.

Full-step Mode

If none of the stator windings are excited, an attraction between the stator polesand rotor teeth still exists because the PM rotor is trying to minimize the reluctanceof the magnetic flux path from one end to the other. As a result, the rotor will tend to rest at one of the rest equilibrium positions. From Fig. 8.1, a rest position existswhen a pair of rotor teeth are aligned with two of the stator poles. In the case ofFig. 8.1, the rotor is aligned with pole 1 and pole 3 on the stator. There are a total of12 possible equilibrium positions for a 4-phase, 6-pole stepper motor. The force ortorque that holds the rotor in one of these positions is called the detent torque. The value of the detent torque is usually small because no current flows through thestator windings.

Half-Step Mode

The stepper motor operation discussed rotates 300 per step. In the half step mode, alternately exciting one winding, then exciting two windings, will cause therotor to move through only 15 degree per step. Though there is a slight loss of thetorque while the single winding is being excited, half-step operation allows forsmoother operation at lower speeds and less overshoot at the end of each step. The excitation sequence of the stator windings in half-step mode is given in Table 8.3.During this operation, each switch between the two nearest modes will cause a 450 shift of stator field which results in a 150 rotation of the rotor. A total of 24steps are required for a complete revolution, double of what is required for full stepmodes.

Micro Step Mode

For the operating modes discussed previously, the same amount of current flows through the energized stator windings. However, if the currents are not equal, the rotor will be shifted towards the stator pole with the higher current. The amount of deviation is proportionate to the values of the currents in each winding. This principle is utilized in the microstep mode. During this mode, each basic full mode step can be divided into as many as 500 microsteps, providing the proper current profile is applied.

- Rotational speed proportional to the frequency of input pulses

- Digital control of speed and position

- No need of feedback sensor for open loop control Excellent acceleration and deceleration responses to step commands

|

| Leadshine 57HS09 Stepper Motor |

The stepper motor has salient poles on both the stator and the rotor, andnormally only the stator poles hold the poly-phase windings called the controlwindings. Usually stepper motors are classified as:

- Active rotor (permanent magnet rotor)

- Reactive rotor (reluctance type)

- Hybrid motors (combining the operating principles of the permanentmagnet (PM) and reluctance stepper motor)

While each of these types of stepper motors has merit, hybrid stepper motorsare becoming more popular in industrial applications. In this chapter, we focus onthe principles and implementation of a hybrid stepper motor control system usingthe LF2407 DSP controller.

The operation of the stepper motor relies on the simple principle of magneticattraction. This principle states that opposite magnetic poles attract while like polesrepel each other. If the windings are excited in the correct sequence, the rotor will rotate following a certain direction. The basic operation of a stepper motor can beclassified generally as either full step mode or half step mode. These modes are discussed in detail in the following section using the simplified stepper motorconstruction shown in Fig. 8.1.

Full-step Mode

If none of the stator windings are excited, an attraction between the stator polesand rotor teeth still exists because the PM rotor is trying to minimize the reluctanceof the magnetic flux path from one end to the other. As a result, the rotor will tend to rest at one of the rest equilibrium positions. From Fig. 8.1, a rest position existswhen a pair of rotor teeth are aligned with two of the stator poles. In the case ofFig. 8.1, the rotor is aligned with pole 1 and pole 3 on the stator. There are a total of12 possible equilibrium positions for a 4-phase, 6-pole stepper motor. The force ortorque that holds the rotor in one of these positions is called the detent torque. The value of the detent torque is usually small because no current flows through thestator windings.

Half-Step Mode

The stepper motor operation discussed rotates 300 per step. In the half step mode, alternately exciting one winding, then exciting two windings, will cause therotor to move through only 15 degree per step. Though there is a slight loss of thetorque while the single winding is being excited, half-step operation allows forsmoother operation at lower speeds and less overshoot at the end of each step. The excitation sequence of the stator windings in half-step mode is given in Table 8.3.During this operation, each switch between the two nearest modes will cause a 450 shift of stator field which results in a 150 rotation of the rotor. A total of 24steps are required for a complete revolution, double of what is required for full stepmodes.

Micro Step Mode

For the operating modes discussed previously, the same amount of current flows through the energized stator windings. However, if the currents are not equal, the rotor will be shifted towards the stator pole with the higher current. The amount of deviation is proportionate to the values of the currents in each winding. This principle is utilized in the microstep mode. During this mode, each basic full mode step can be divided into as many as 500 microsteps, providing the proper current profile is applied.

2016年9月8日星期四

Spindle Motors

The motor that spins the platters is called the spindle motor because it is connected to the spindle around which the platters revolve. Spindle motors in hard disk drives are always connected directly; no belts or gears are involoved. The motor must be free of noise and vibration; otherwise, it can transmit a rumble to the platters, which can disrupt reading and writing operations.

The spindle motor also must be precisely controlled for speed. The platters in hard disk drives revolve at speeds ranging from 3600rpm to 15000rpm (60-250 revolutions per second) or more, and the motor has a control circuit with a feedback loop to monitor and control this speed precisely. Because the speed control must be automatic, hard drives do not have a motor-speed adjustment. Some diagostics programs claim to measure hard drive rotation speed, but all these programs do is estimate the rotational speed by the timing at which sectors pass under the heads.

There is actually no way for a program to meause the hard disk drive's rotational speed; this measurement can be made only with sophisticated test equipment. Don't be alarmed if some diagnostics program tells that your drive is spinning at an incorrect speed; most likely, the program is wrong, not the drive. Platter rotation and timeing information is not provided through the hard disk controller interface. In the past, software could give approximated rotational speed estimates by performing multiple sector read requests and timing them, but this was vaild only when all drives had the same number of sectors per track and spun at the same speed. Zoned-bit recording combined with the many various rotational speeds used by modern drives, not to mention built-in buffers and caches-means that these calcualtion estimates can't be performed accurately by software.

On most drives, the spindle motor is on the bottom of the drive, just below the sealed HDA. Many drives today, however have the spindle motor built directly into the platter hub inside the HDA. By using an intermal hub spindle motor, the manufacture can stack more platter in the drive because the spindle motor takes up no vertical space.

Traditionally, spindle motors have used ball bearings in their design, but limitations in their performance have now caused drive manufactures to look for alternatives. The main problem with ball bearings is that they have approximately 0.1 micro inch (millionths of an inch) of runout, which is lateral of modern drives, it has become a problem. This runout allows the platters to move randomly that displus the metal-to-metal contact nature of ball bearings allows an excessive amount of mechanical noise and vibration to be generated, and that is becoming a problem for drives that spin at higher speeds.

The solution is a new type of bearing called a fluld dynamic bearing, which uses a highly viscous lubrication flud between the spindle and sleeve in the motor. Thi flud serves to dampen vibrations and movement, allowing runout to be reduced to 0.01 micro inches or less. Fluid dynamic bearings also allow for better shock resistance, improved speed control, and reduced noise generation. Several of the more advanced drives on the market today already incorporated fluid dynamic bearings, especially those designed for very high spindle speeds, high areal densities, or low noise. Over the next few years, I expect to see fluid dynamic bearings become standard issue in most hard drives.

The spindle motor also must be precisely controlled for speed. The platters in hard disk drives revolve at speeds ranging from 3600rpm to 15000rpm (60-250 revolutions per second) or more, and the motor has a control circuit with a feedback loop to monitor and control this speed precisely. Because the speed control must be automatic, hard drives do not have a motor-speed adjustment. Some diagostics programs claim to measure hard drive rotation speed, but all these programs do is estimate the rotational speed by the timing at which sectors pass under the heads.

There is actually no way for a program to meause the hard disk drive's rotational speed; this measurement can be made only with sophisticated test equipment. Don't be alarmed if some diagnostics program tells that your drive is spinning at an incorrect speed; most likely, the program is wrong, not the drive. Platter rotation and timeing information is not provided through the hard disk controller interface. In the past, software could give approximated rotational speed estimates by performing multiple sector read requests and timing them, but this was vaild only when all drives had the same number of sectors per track and spun at the same speed. Zoned-bit recording combined with the many various rotational speeds used by modern drives, not to mention built-in buffers and caches-means that these calcualtion estimates can't be performed accurately by software.

On most drives, the spindle motor is on the bottom of the drive, just below the sealed HDA. Many drives today, however have the spindle motor built directly into the platter hub inside the HDA. By using an intermal hub spindle motor, the manufacture can stack more platter in the drive because the spindle motor takes up no vertical space.

Traditionally, spindle motors have used ball bearings in their design, but limitations in their performance have now caused drive manufactures to look for alternatives. The main problem with ball bearings is that they have approximately 0.1 micro inch (millionths of an inch) of runout, which is lateral of modern drives, it has become a problem. This runout allows the platters to move randomly that displus the metal-to-metal contact nature of ball bearings allows an excessive amount of mechanical noise and vibration to be generated, and that is becoming a problem for drives that spin at higher speeds.

The solution is a new type of bearing called a fluld dynamic bearing, which uses a highly viscous lubrication flud between the spindle and sleeve in the motor. Thi flud serves to dampen vibrations and movement, allowing runout to be reduced to 0.01 micro inches or less. Fluid dynamic bearings also allow for better shock resistance, improved speed control, and reduced noise generation. Several of the more advanced drives on the market today already incorporated fluid dynamic bearings, especially those designed for very high spindle speeds, high areal densities, or low noise. Over the next few years, I expect to see fluid dynamic bearings become standard issue in most hard drives.

2016年9月6日星期二

Mechanical Overview of Servo Motors

Servo motors have serval distinct characteristics that sperate them from their stepper counterparts. The biggest is the lack of direct gearing between the rotor and the output shaft. This eliminates the backlash and cogging behaviors found ins steppers, where there is period of slop between the gear teeth before movement actually begins, and where the shaft continues to move after the motor has stopped. This can lead to jerky starts and stops, as well as a time delay in movement. This does not impede static positioning performance markedly, but it presents major issues when on-the-fly velocity changes or hard starts/stops are needed.

A model of a typical radial brushless DC servo motor is shown before in figure 1.1 For a long time, servo motors used brushes to transfer current from the static winding to the rotor, but this would lead to wear on the brushes, in turn shortening the lifespan of the motor. With the advent of electronic motor controllers, the brusheless design was adopted, which uses control electronics to vary the currents phases to the motor's windings in the same way the brushes do. For the rest of this paper, all mention of servo motors will be of the brusheless type.

Looking at figure 1.1 below, there are several objects of interest. First are the armature windings (held by the stator), which create a magnetic field that travels through the air gap to the permanent magnets on the rotor. Even though there are normally no gears in a servo motor, cogging can still exist, as there are gaps between the magnets on the rotor where the flux decrease, though this only becomes noticeable at low speeds. This type of congging in servos is perhaps more accurately termed "detent torque." There are two ways to minimize this type of cogging, the most common being the addition of some gearing to the drive shaft. This allow the motor to run at a higher speed out of its cogging region, but does not compromise power output or precision, thought it can induce some backlash. The other way of minimizing cogging is to skew the magnets on the rotor so that a radial line from the center of the rotor always intersects a magnet at least once. When using a motor without gearing, it is known as a direct drive motor. This allows for the best transfer of power to the load, and avoids any of the negative aspects of gearing previously mentioned. A feature in newer servo motors (including the Bodine models used in this thesis) is the use of an ironless stator, which eliminates iron saturation, a situation where the magnetic properities of the iron limit how much current can be applied to the windings. Inducing iron saturation too ofen will cause overheating and possibly damage the winding or magnets. With an ironless stator, rotor magnet skewing is not necessary, as the magnetic fields aren't influenced by the material of the stator. Also, since the only mechanical connection between the shaft and the body is through the bearings, friction is very low (especialy when using ball bearings).

In high torque motors such as the ones used in this thesis, the rotor actually consists of two plates of permanet magnets sandwiching the stator, which allows for a major increase in torque. This feature only exists in axial flux motors, due to the design where the stator lies in between the rotors, whereas in radial flux servos, the rotor is completely enclosed by the stator. The majority of the heat dissipated from a servo motor comes from the stator, so its outside location adis in cooling. In fact, the main limiting fator in the power of a servo motor is the heat capacity of the stator and the armature windings.

Fasttobuy Servo Motor On Sale In this September

If you are interested in these servo motor, you can click this link: https://www.fasttobuy.com/specials.html

A model of a typical radial brushless DC servo motor is shown before in figure 1.1 For a long time, servo motors used brushes to transfer current from the static winding to the rotor, but this would lead to wear on the brushes, in turn shortening the lifespan of the motor. With the advent of electronic motor controllers, the brusheless design was adopted, which uses control electronics to vary the currents phases to the motor's windings in the same way the brushes do. For the rest of this paper, all mention of servo motors will be of the brusheless type.

Looking at figure 1.1 below, there are several objects of interest. First are the armature windings (held by the stator), which create a magnetic field that travels through the air gap to the permanent magnets on the rotor. Even though there are normally no gears in a servo motor, cogging can still exist, as there are gaps between the magnets on the rotor where the flux decrease, though this only becomes noticeable at low speeds. This type of congging in servos is perhaps more accurately termed "detent torque." There are two ways to minimize this type of cogging, the most common being the addition of some gearing to the drive shaft. This allow the motor to run at a higher speed out of its cogging region, but does not compromise power output or precision, thought it can induce some backlash. The other way of minimizing cogging is to skew the magnets on the rotor so that a radial line from the center of the rotor always intersects a magnet at least once. When using a motor without gearing, it is known as a direct drive motor. This allows for the best transfer of power to the load, and avoids any of the negative aspects of gearing previously mentioned. A feature in newer servo motors (including the Bodine models used in this thesis) is the use of an ironless stator, which eliminates iron saturation, a situation where the magnetic properities of the iron limit how much current can be applied to the windings. Inducing iron saturation too ofen will cause overheating and possibly damage the winding or magnets. With an ironless stator, rotor magnet skewing is not necessary, as the magnetic fields aren't influenced by the material of the stator. Also, since the only mechanical connection between the shaft and the body is through the bearings, friction is very low (especialy when using ball bearings).

In high torque motors such as the ones used in this thesis, the rotor actually consists of two plates of permanet magnets sandwiching the stator, which allows for a major increase in torque. This feature only exists in axial flux motors, due to the design where the stator lies in between the rotors, whereas in radial flux servos, the rotor is completely enclosed by the stator. The majority of the heat dissipated from a servo motor comes from the stator, so its outside location adis in cooling. In fact, the main limiting fator in the power of a servo motor is the heat capacity of the stator and the armature windings.

Fasttobuy Servo Motor On Sale In this September

If you are interested in these servo motor, you can click this link: https://www.fasttobuy.com/specials.html

订阅:

博文 (Atom)